Mohali: Researchers at the Institute of Nanoscience and Technology (INST) unveiled a “groundbreaking” water purification system that harnesses sunlight, gentle vibrations, and artificial intelligence (AI) to tackle industrial wastewater pollution. This biodegradable, eco-friendly, and low-cost technology, detailed in the journal Nano Energy, offers a sustainable solution to the global challenge of water contamination, particularly from harmful dyes like Methylene Blue and Congo Red, which are discharged by textile and pharmaceutical industries. These dyes not only discolour water but also threaten ecosystems and human health, causing skin and respiratory issues. Unlike traditional methods such as electrochemical or ozone treatments, which are energy-intensive and rely on costly, hazardous chemicals, this innovation minimises environmental impact while maximising efficiency.

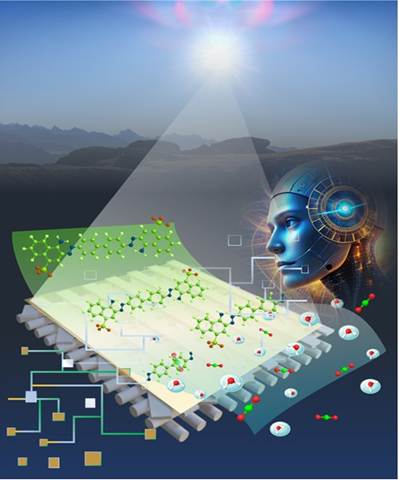

Led by Dr. Aviru Basu, the INST team developed a 3D-printed scaffold made from polylactic acid (PLA), a biodegradable polymer known for its eco-safety and compatibility. Coated with Bismuth Ferrite (BiFeO₃), a catalyst renowned for its piezoelectric and photocatalytic properties, the scaffold enables a process called piezo-photocatalysis. Sunlight excites electrons in BiFeO₃, triggering redox reactions that break down dye molecules, while vibrations—generated by environmental movements or ultrasonic sources—enhance the catalyst’s piezoelectric response, ensuring performance even on cloudy days. This dual-action mechanism overcomes the limitations of conventional solar-powered purification, which falters without consistent sunlight. The system achieved remarkable results, removing 98.9% of Congo Red and 74.3% of Methylene Blue from wastewater samples, surpassing many high-end treatment methods.

To optimise performance, the researchers employed machine learning, specifically Artificial Neural Networks (ANNs), to predict the system’s efficiency under varying conditions with up to 99% accuracy. This AI-driven approach allowed fine-tuning of the purification process, ensuring maximum pollutant degradation. The development process involved synthesising BiFeO₃ nanoparticles via a sol-gel method, fabricating 3D-printed PLA scaffolds, coating them with the catalyst, and conducting rigorous dye degradation tests. The result is a reusable, scalable technology that avoids excessive chemical use and aligns with renewable energy principles, harnessing sunlight and vibrations instead of fossil fuels.

The innovation’s focus on biodegradable materials and low-cost production makes it a game-changer for both industrial and remote community applications. By addressing the environmental and health risks posed by industrial dyes, the system supports sustainable development goals, reducing the ecological burden of wastewater. Discussions are underway to integrate this technology into existing wastewater treatment frameworks, particularly in high-pollution industrial zones, with potential for large-scale adoption. The use of eco-friendly materials like PLA ensures a minimal environmental footprint, aligning with global calls for sustainable water management.

This breakthrough reflects a growing trend in interdisciplinary solutions, combining nanoscience, renewable energy, and AI to address pressing environmental challenges. Social media posts have highlighted public enthusiasm for such sustainable technologies, emphasising their potential to transform water purification. As industries and communities seek cleaner water solutions, INST’s innovation offers a scalable, cost-effective path forward, paving the way for a future where clean water is accessible without compromising the environment.

– global bihari bureau