Mohali: Nano-material coating developed by scientists from the Institute of Nano Science and Technology (INST) can increase the efficiency of fertilisers by slowing down their release.

Scientists from INST coated muriate of potash (KCl), which serves 80% of potassium fertilizer needs, with binary carbohydrates, namely, chitosan and lignin using anionic clay as a reinforcement agent that favours stable coordination bonds.

The mechanically stable, biodegradable, hydrophobic nanocoating material can enhance the nutrient use efficiency of chemical fertilisers by tuning them for slow release, thereby limiting their interaction with the rhizosphere soil, water and microbes. This coating of nano clay-reinforced binary carbohydrates can reduce the recommended fertiliser dose and enhance crop production.

Since the last 50 years, as part of the green revolution, frequent chemical fertilizer input practices have been used to maintain soil nutrients so that higher plant productivity can be achieved. The frequent and excessive application poses risks to global sustainable development. Therefore, researchers are constantly on the lookout for ways to use fertilisers more efficiently.

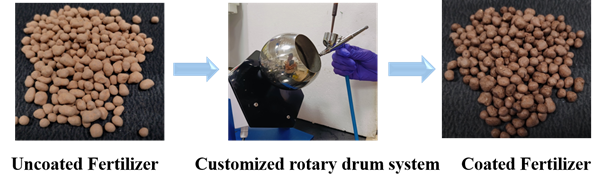

INST’s BK Sahu, K Swami, N Kapoor, A Agrawal, S Kataria, P Sharma, P. Kundu, H. Thangavel, A. Vattakkuniyil, O. P. Chaurasia and V. Shanmugam used drum rotor method to coat the fertilizer in a uniform manner and improve the use efficiency. The nanomaterials used for the uniform coating were nature-derived low-cost materials like nano-clay, chitosan, starch and so on. The research has been published in the journal Environmental Science: Nano.

Tuning the hydrophobicity of nano-coating material switched the release kinetics of the chemical fertilizers as per crop requirement. Additionally, the biodegradability and life cycle assessment of the developed product ensured the sustainability over conventional chemical fertilisers. Further, the mechanical performance of the coated fertiliser guarantees its industrial application during transportation and supply chain.

The 3D nanostructure of nature-inspired polymers offers a potential platform for various applications with the advantage of its biocompatibility and biodegradability. The properties of natural waste polymers like irreversible denaturation, self-assembled amyloid fibril formation and thermos-responsiveness were exploited for assembling hydrophobic nanomaterial for the slow release of chemical fertilisers. Further, the customized rotary drum system with sand air gun enabled the uniform coating of chemical fertilisers with “excellent mechanical performance”.

The slow-release fertilisers can be the potential alternative to conventional fertilisers to enhance nutrient use efficiency. The reduced recommended dose with increased yield of rice and wheat facilitates more output from lesser input. Overall, the socio-economic condition of the farmer and the economy of the country will improve as compared to conventional fertiliser applications.

– global bihari bureau